Like any other profession, the people who intend to join the metal fabrication field are curious about how many jobs are available in metal fabrications. It’s time to think positively and explore the related aspects to sort things smoothly. Imagine a world without buildings, bridges, automobiles, or even kitchenware; all are products of the robust metal fabrication industry. This resilient sector, often overlooked, saw a sales growth of 34.9% in 2021, with almost 60% of industry participants reporting that their sales growth surpassed 25%. This growth trajectory makes you wonder is metal fabrications is a good career path. Despite challenges such as supply chain disruptions, which dipped on-time deliveries from 87% in 2020 to 77%, and the surge in material costs that currently represent 39% of sales, up from 34% the prior year, the metal fabrication industry continues to be a pillar of strength. This unsung hero plays a pivotal role in our day-to-day lives, serving as the backbone of multiple industries, particularly steel/iron ore, and significantly contributing to global economies offering metal fabrications a good career path.

Understanding Metal Fabrication

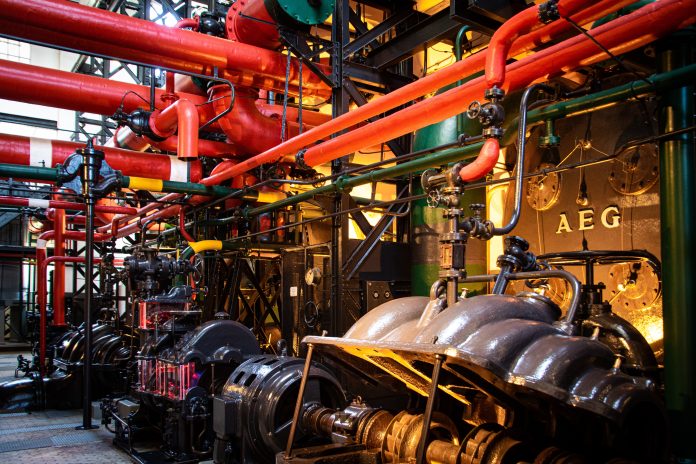

The metal fabrication process, a fundamental component of the industrial world, is a complex sequence where raw metal materials are processed to create finished, usable products. The process is versatile and widely applicable, used in mass production and custom fabrication jobs. The steps involved are cutting, bending, and assembling the materials, with each phase demanding meticulous precision and profound comprehension of the material and techniques. Various materials, such as steel, aluminum, and copper, fabricate multiple products. From practical career considerations like the suitability of aluminum fabrication to the construction of grand structures like bridges or crafting smaller daily-use items like kitchen utensils and car parts, the reach of metal fabrication extends to nearly every facet of modern living. It helps remove the confusion regarding whether is aluminum a good career path.

The Role of Metal Fabrication in Infrastructure Development

Metal fabrication plays an undeniably crucial role in infrastructure development across the globe. Metal fabrication is indisputably at the heart of modern civilization, from constructing sturdy bridges, sprawling highways, and towering buildings to manufacturing sleek vehicles, efficient machinery, and indispensable tools. With urbanization and infrastructure development witnessing a significant upsurge, especially in emerging economies, the demand for metal fabrication services is anticipated to follow an upward trajectory. It is great hope for those looking for the answer to their query about how many jobs are available in metal fabrications. This robust growth underlines the strategic importance of the metal fabrication industry in fostering global economic development and societal progress.

Globalization and the Metal Fabrication Industry

Globalization is an influential trend considerably impacting the metal fabrication industry. The interconnected global economy empowers fabricators to source materials, sell products, and outsource specific tasks internationally. While this has undoubtedly unfolded new opportunities, it simultaneously brings challenges such as amplified international competition, supply chain complexities, and the need to comply with diverse regulatory norms across different markets. Understanding these global dynamics and navigating through them is crucial for sustained success in the modern-day metal fabrication industry.

The Current State of the Metal Fabrication Industry

Over the years, the landscape of the metal fabrication industry, including that of national metal fabricators, has been continually evolving and expanding. There is little concern over how many jobs are available in metal fabrications. Technological breakthroughs have impacted the industry indelibly, making fabrication processes more efficient, secure, and precise. Automation, computer-aided design, and manufacturing have revolutionized fabrication techniques, streamlining the production process and improving accuracy. Economically speaking, metal fabrication has significantly contributed to the global market. It is the mainstay of numerous industries, such as construction, automotive, aerospace, and others. Not only has the enterprise prospered, but the metal fabrication salary has also seen a consistent upward trend, attracting more professionals to this sector.

Job Opportunities in Metal Fabrication

With the industry’s evolution comes a surge in job demand. The metal fabrication industry is a treasure trove of opportunities, with various roles catering to diverse skills and interests. For those pondering over any jobs are available in metal fabrications– the answer is a resounding yes. The industry teems with high-paying jobs in metal fabrication, including specialized roles like welding fabrication jobs. If you are searching for steel fabrication jobs near me, many opportunities are just a click away. Key roles range from welders, metal fabricator, and CNC operators to quality control inspectors and supervisory positions. Each role is unique, demanding various skills, from executing intricate fabrication processes to ensuring stringent quality standards and overseeing operations on the shop floor.

Career Path and Progression in the Metal Fabrication Industry

When it comes to career progression, metal fabrication careers offer immense potential. Starting from entry-level positions, individuals can climb the ladder to attain mid-level and managerial roles. They can leave significant impacts on projects, processes, and people. Specialization within the industry opens doors to more advanced roles, focusing on niche areas and offering opportunities for growth and learning. The rewards for such dedication are substantial. Competitive metal fabrication salaries and additional benefits reflect the value these professionals bring to their organizations. The steel/iron ore is a good career path too holds great potential.

Sustainability in Metal Fabrication

Sustainability has emerged as an integral facet of the metal fabrication industry. Green fabrication methods aim to curtail waste, optimize resource utilization, and decrease the industry’s environmental footprint. This progressive approach entails a comprehensive spectrum of practices, from using recycled materials and energy-efficient machinery to implementing robust waste management systems and cutting down on harmful emissions. As the global focus progressively shifts towards sustainable practices, fabricators must adapt to meet these evolving expectations, thereby turning ‘green’ into a tangible competitive advantage and opening doors for those who want to know how many jobs are available in metal fabrications.

Training and Education for Metal Fabrication Jobs

The metal fabrication industry values practical experience and hands-on training. While an educational background in related fields is a plus, vocational training, and apprenticeships are vital entry points for aspiring fabricators. These offer them a real-world understanding of the job, equipping them with valuable practical knowledge. Acquiring industry-specific certifications and licenses gives an individual a competitive edge, enhancing employability. The ever-evolving nature of this industry necessitates continuous education and upskilling for those wishing to stay relevant. If you’re searching for sheet metal jobs near me, ensure you’re well-equipped with the right skills and knowledge.

Safety Considerations in Metal Fabrication

Safety is of paramount importance in the metal fabrication industry. The nature of the metal fabrication work involves handling hefty materials, operating sophisticated machinery, and working close to intense heat, all of which demand stringent safety protocols. Employees should have necessary personal protective equipment, including helmets, gloves, and safety glasses. In addition to these, comprehensive training and continuous reinforcement of safety measures are essential to curb the possibility of workplace accidents. Also, upholding a clean, orderly workspace can substantially minimize the risk of untoward incidents, creating a safer and more productive work environment.

Technological Innovations in Metal Fabrication

Technology is driving the future of the metal fabrication industry. Innovations such as 3D printing, laser cutting, and robotic welding are transforming traditional fabrication methods and creating more opportunities for those looking to answer the query regarding how many jobs are available in metal fabrications. Automated production lines and computer-aided design tools enhance precision and efficiency, allowing for complex, high-quality products. Machine learning and predictive analytics are helping in better forecasting and decision-making. At the same time, digital twins and augmented reality provide immersive planning and training environments. Embracing these new technologies is crucial for competitiveness in an increasingly digital future.

The Future of Jobs in the Metal Fabrication Industry

Peering into the future, industry forecasts paint an optimistic picture of job market growth in metal fabrication, revealing to the aspirants that many jobs are available in metal fabrications. Despite concerns of job displacement due to automation and AI, the reality is that these advancements are creating new roles requiring skilled oversight. They are also contributing to creating a myriad of jobs in metal fabrication. The increasing emphasis on sustainable practices and green technology also augurs well for job creation. It calls for professionals adept at implementing eco-friendly fabrication methods, thereby broadening the scope of job opportunities in the sector.

Conclusion

The metal fabrication industry is a vibrant and diverse space with endless opportunities. To an outsider looking in, it may appear as an environment dominated by machines and metals. On the contrary, if you look closer, you will discover an arena filled with creative problem-solving, technical mastery, teamwork, and problem-solving skills. If crafting tangible products while contributing to essential industries is your passion, then metal fabrication might be for you. Don’t wait for another second and explore it further. A whole new world is waiting for you!!

FAQs about Jobs in Metal Fabrication

What is metal fabrication?

Metal fabrication involves cutting, bending, and assembling metal materials to create diverse products.

What kinds of jobs are available in metal fabrication?

Several jobs are available, including positions like welders, fabricators, CNC operators, quality control inspectors, and supervisory.

What qualifications do I need for a job in metal fabrication?

Typically, you would need vocational training and hands-on experience. For specific jobs, certifications from professional bodies may be necessary.

Is the metal fabrication industry expected to grow in the future?

Yes, the metal fabrication industry is expected to grow. Technological advancements and sustainability trends will likely create new job roles and opportunities.